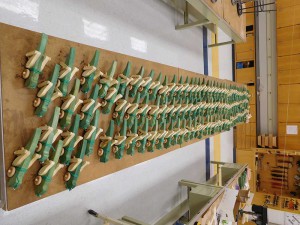

Hand-made toy crickets are stored on a rack in the Unionville High School Tech Ed. Department. The toys — which will be given to area boys and girls in need through the U.S. Marines’ Toys For Tots program — are entirely built and designed by the school’s students, a tradition now dating back a decade.

EAST MARLBOROUGH — While Santa’s Workshop is justifiably well-known for making countess toys every year, a local workshop has been cranking out some of the most amazing hand-made wooden toys for area kids in need for almost a decade now.

The Tech Education department of Unionville High School — along with gathering toys as part of the United States Marines’ Toys for Tots program — has been hand-building amazing wooden toys, a project allowing students to give back to greater community while learning skills.

Students sand the toys prior to staining and assembly. From left: Brady Horne, Molly Hutter, Elan Nash, Ryan Dreher, Mark Maggitti and Megan Belgam.

Under the direction of long-time Tech Ed teacher Mike Berkeheiser and other faculty members, students create a toy concept, design it and finally build roughly 100 toys for area kids in need. With seed money from the school’s PTO, this year, the students built pull-along wheeled crickets, hand-painted and with articulating legs, to allow them to pop up and down when pulled by a child.

Each year, students and faculty create toys for young children that blend the latest in high-tech design with old-world craftsmanship.

Although a lot of high-tech goes into building the toys, they also require old-school, hands on work, including hand staining each one of them. Here’s students apply green stain to the cricket bodies. From left students hard at work: Lindsay Cicchino, Sean Green, David Hagerty, Joe Impaglia, Brody McShane and Anarose McDonough At the right rear, teacher Steve Ortega supervises.

It is important to understand that the production process was much like that of many professional shops, and not like the casual hobbyist. The students use computer-aided design software (CAD) to design the toys — particularly important with toys that have moving parts. The simulations sort through the toys’ motions and any potential conflicts or issues before the first piece of wood is cut. Students then use a computer controlled router to cut out the basic shapes before handwork begins on the item.

Although a lot of technology is involved, a great deal of old-fashioned wood-working is also involved. Students hand sand each of the pieces of wood — crucial to eliminate all potential splinters in toys intended for young children. Then each piece is hand-stained by students, prior to final assembly.